Videoline 204-RP

Professional test lane PC based. Modular configuration to meet all requirements

Professional test lane PC based. Modular configuration to meet all requirements

Test lane meet your individual requirments.

Customised operation of testing equipment

Latest technology for highest flexibility.The RP box with integrated electronics is the technological core of the system. Communication with the workstation or the display kit is wireless, which allows flexible and simple installation

The workstation is supplied with control unit, 27“ TFT flat screen, A4 inkjet printer, keyboard and mouse and an extended software package

These built-in frames considerably facilitate preparation of foundations. There is no need to embed in concrete a steel beam with edge guards which is otherwise inevitable. None the less built-in frames are always exactly level with ground.

Professional test lane PC based. Modular configuration to meet all requirements

Mechanics in compact flat design, hot dip galvanised, suitable for outdoor installation

Equipped with rust-proof feeler rolls

Level rollers

4t drive-over weight (axle)

Roller length 700 mm, with Composite coating

Splash-proof motors 3.7kW

Electric automatic drive-off aid to facilitate driving off the rollers

4WD mode (counter-rotation)

Dual direction testing: to drive on the rollers from both sides and test in both directions

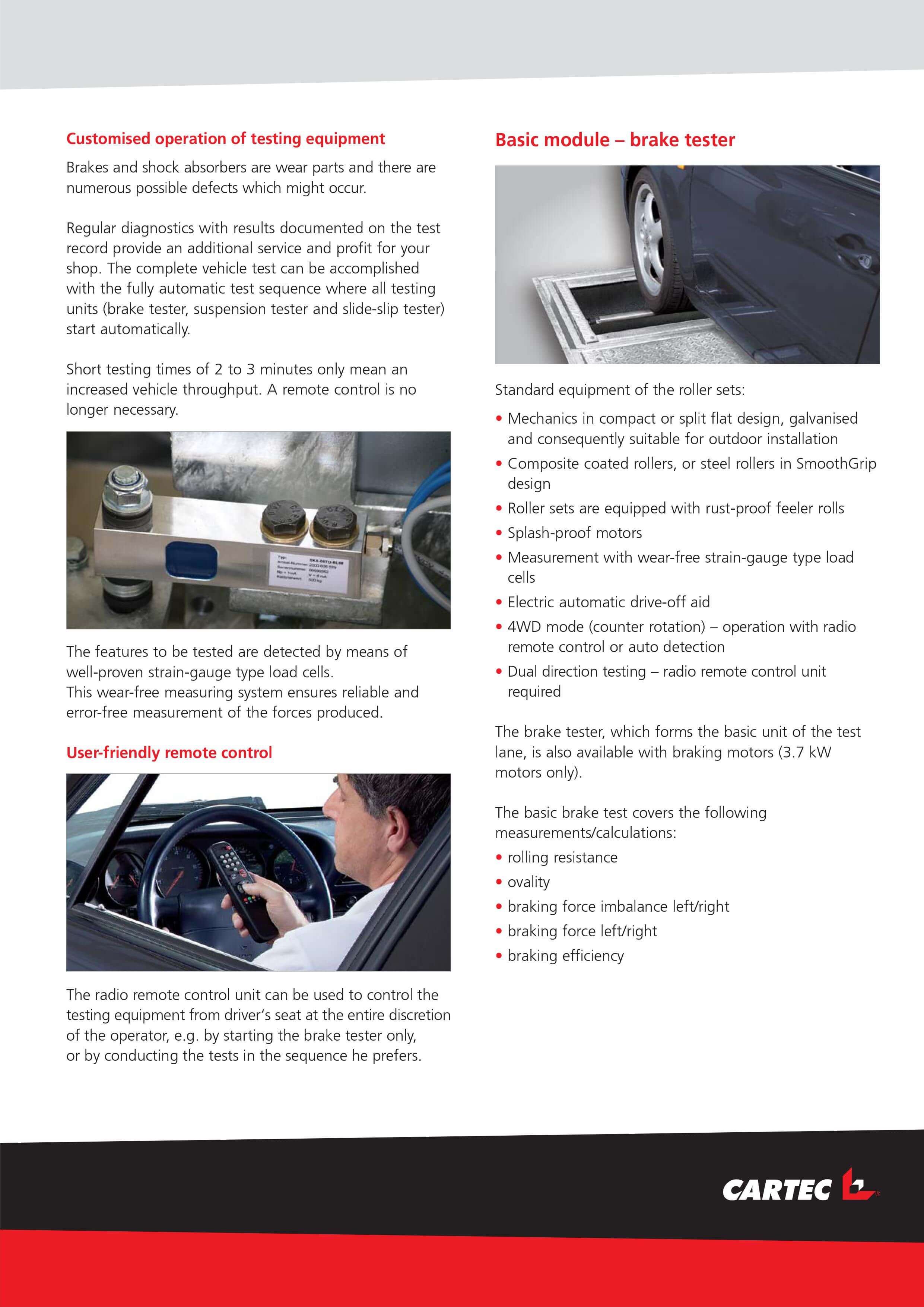

The RP box with integrated electronics is the technological core of the system

Wireless communication with the workstation, which allows flexible and simple installation

Lockable main switch integrated

Radio remote control grants simple operation in any conditions

Design, which recalls the legendary Snap-on tool storage

Equipped with wheels, two of them with brakes

VESA monitor support

Integrated power supply module

Supplied with: control unit (PC), keyboard, mouse, 27” TFT flat monitor, A4 ink jet printer

Possible use of portable controller device such as a tablet PC

Extended software package

Axle load weighing unit

Radio pedal pressure transducer PK 2.0

Radio transmission. In contrary to infrared transmission, there are no malfunctions because of external influences like sunlight, persons or objects standing in the way. The operation is customer-friendly, and independent of where the transmitter is standing.

Compact design with rollers 700 mm long: the standard solution for cars and vans

Compact design with rollers 1000 mm long: the solution for for cars, vans, caravans and trailers with tandem axles

Split design with rollers 700 mm long: the solution to be mounted on the side of the pit

Split design with rollers 1000 mm long: due the variable test width, can be used to test, beside cars and vans, motorcycle, three wheeler, quads

All mentioned version are available with motors 2 x 3,7 kW (max brake force 6 kN) or 2 x 5 kW (max brake force 7 kN)

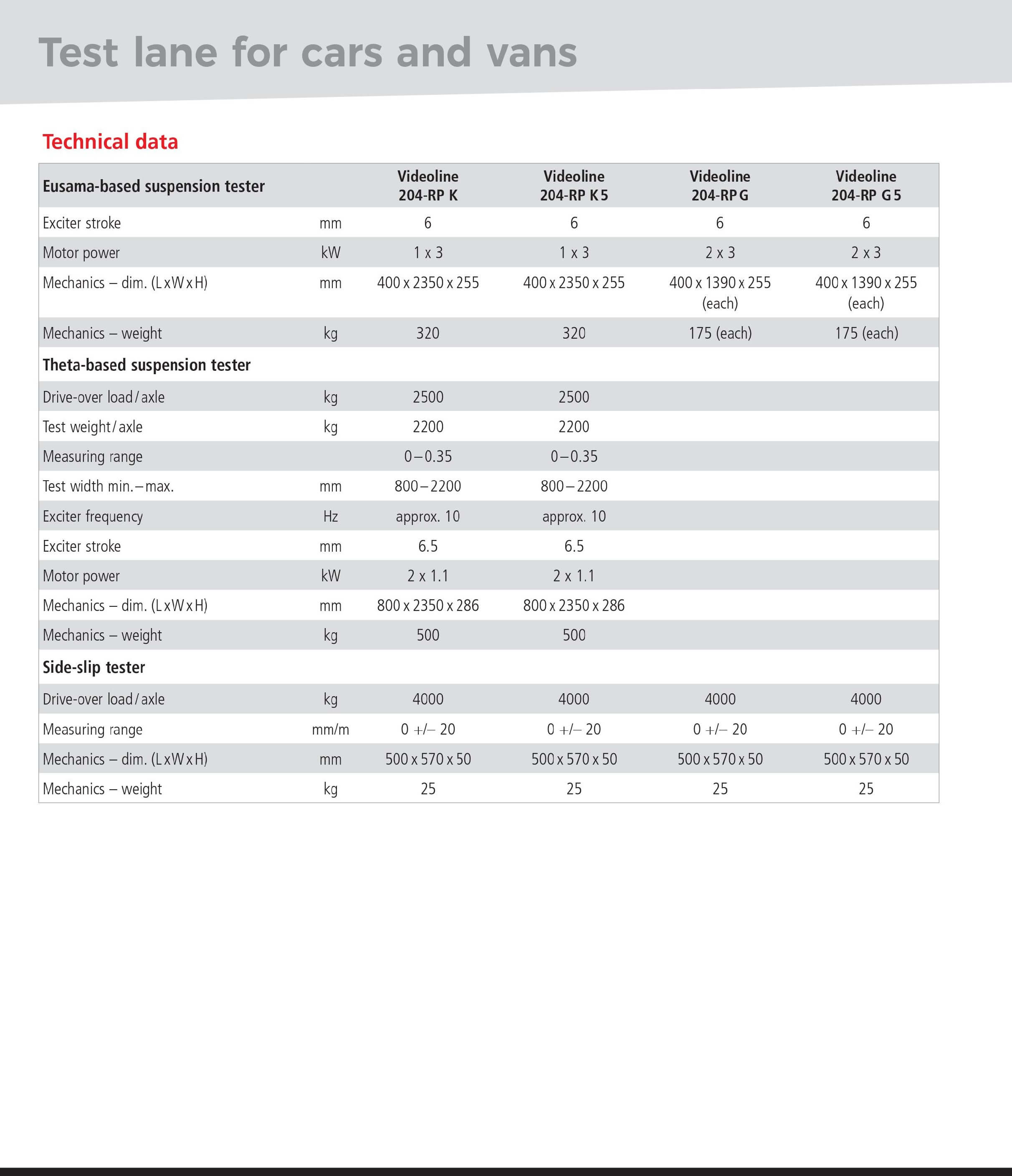

Suspension tester, Eusama principle, in compact design

Suspension tester, Theta principle, in compact design, with noise research module

Side-slip tester, 500 or 1000 mm long

Options:

Motor brake for preserving motor and gear during drive out of the roller set (only for 3,7 kW)

Soft-start module for reduce the electric current absorption during starting of the motors

Integrated axle load weighing system or installation kit for later retrofit of the weighing system

Swivel wall support or column for virtual analogue display

Heating system for virtual analogue display, version for outdoor installation

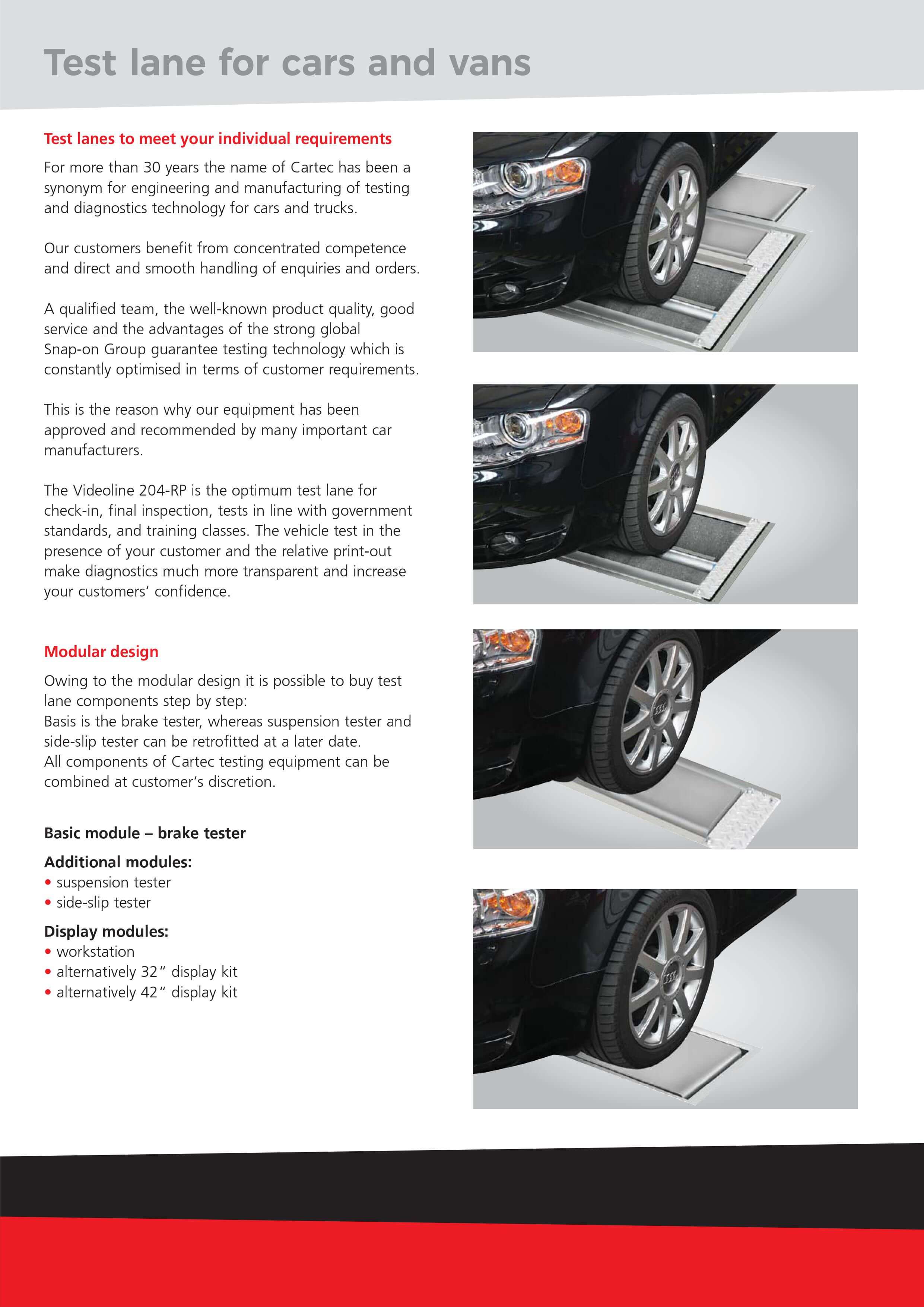

Pneumatic lifting device: raises the vehicle to ground level, driving in and off the rollers is considerably facilitated and hence especially advantageous for vehicles with sports chassis or small wheel diameters

Lifting device of the roller set (only for compact design with roller length 1000 mm) is the ideal solution to help in performing the right test on vehicles with twin axles

Pedal pressure transducers cable or radio version

Pit safety devices 3 or 5 points for split versions

Roller covers hinged outwards or plug-in

Adapter for testing 2 wheels motorcycles

Noise level module for suspension tester, Eusama principle

Wide range of build-in frames (to facilitate the preparation of foundation)

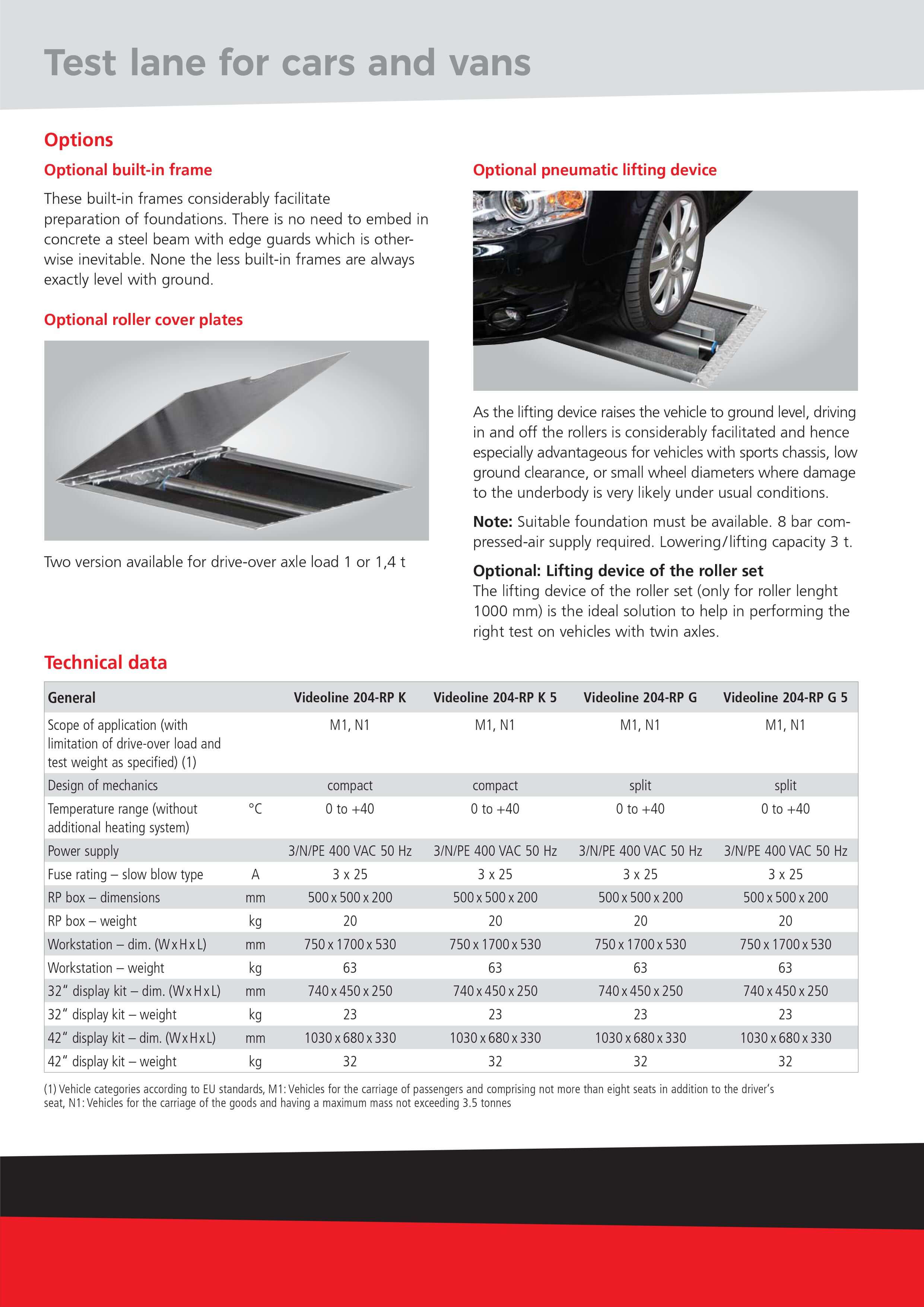

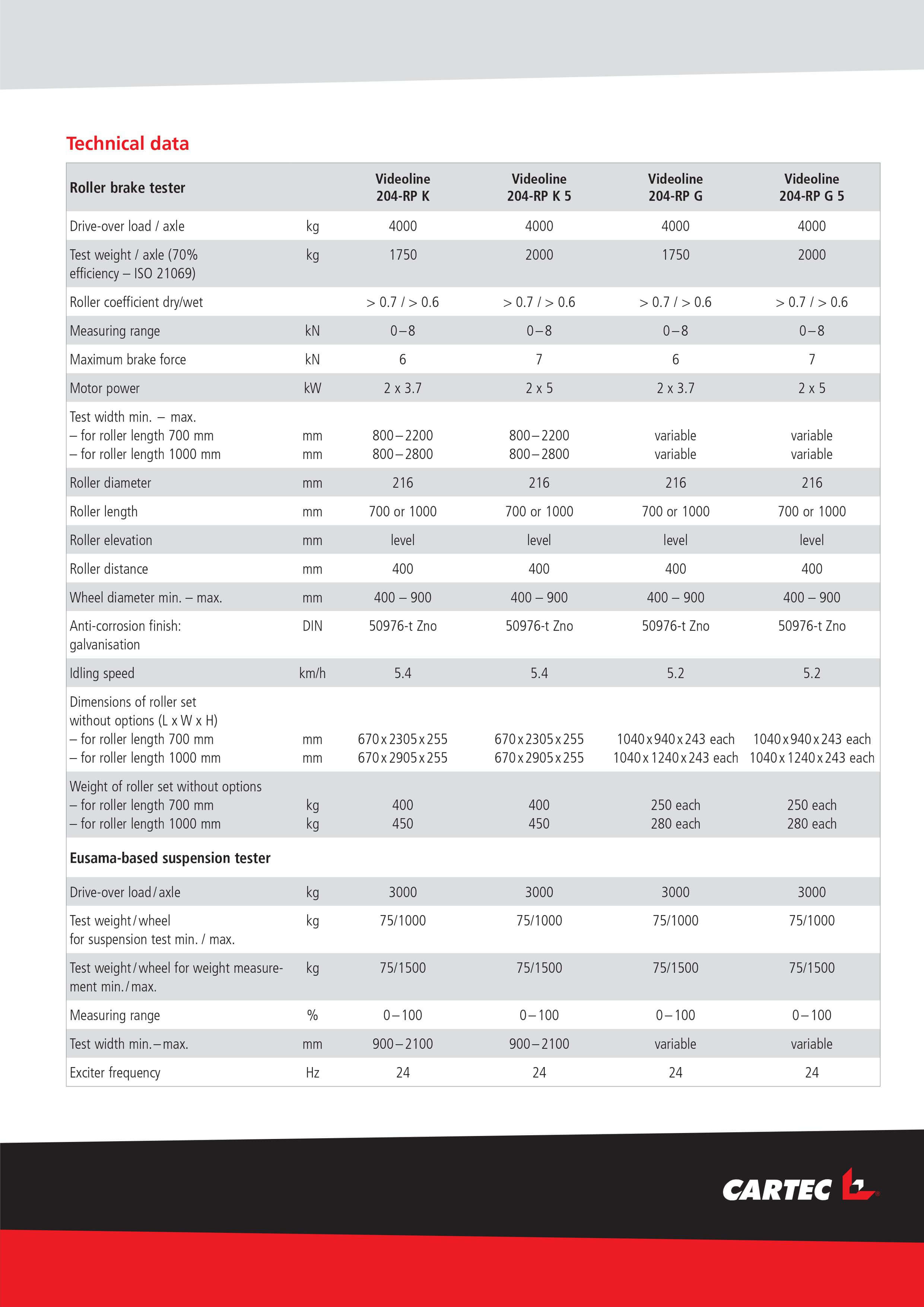

Max. drive over weight per axle: 4000 kg

Measuring range: 0 – 8000 N

Max. brake force: 6000 N (with 2 x 3,7 kW motors) 7000 N (with 2 x 5 kW motors)

Test weight per axle according ISO 21069 (70% braking efficiency): 1750 kg (with 2 x 3,7 kW motors) 2000 kg (with 2 x 5 kW motors)

Idling speed: 5,4 km/h (roller set compact design) 5,2 km/h (roller set split design)

Roller coefficient dry wet: > 0.7 / > 0.6

Motor power: 2 x 3,7 kW or 2 x 5 kW

Roller diameter: 216 mm

Roller length: 700 or 1000 mm

Test width: 800 – 2200 mm (compact design rollers 700 mm) 800 - 2800 mm (compact design rollers 1000 mm) variable (split design) for suspension and side slip tester refer to the corresponding section